From Conventional to Intelligent: How 5-Axis Machining Centers Improve Stability in Energy Equipment Production

As energy equipment design trends toward lighter structures, larger geometries and higher performance tolerances, conventional multi-step machining workflows increasingly struggle to deliver consistent accuracy and throughput. Manufacturers of wind turbine housings, hydro turbine components and large gas-compression parts face three recurring challenges: complex part geometry, multiple setups that introduce cumulative error, and thermally induced drift during long cycles. Five-axis gantry-moving-column machining centers address these pain points by combining multi-degree-of-freedom kinematics, rigid structural design and intelligent control to raise processing stability while shortening process chains.

Industry pressures and machining challenges

Energy equipment manufacturers increasingly require large, asymmetric parts with surface finishes and geometric tolerances that were previously uncommon in this sector. Key implications for shop floors include:

- Higher number of setups per part — each setup introduces indexing error and adds lead time.

- Long cycle durations raise the risk of thermal growth and axis drift, undermining dimensional stability.

- Material choices (aluminum alloys, titanium, composites) demand precise tool paths and adaptive cutting strategies.

For reference, many conventional multi-fixture workflows for large energy components require 3–8 separate setups and can generate scrap or rework rates in the range of 3–8% on new part families as processes stabilize.

Limitations of traditional 3-axis and indexed 5-axis approaches

Traditional 3-axis machining and indexed rotary-table approaches still have a place, but they face intrinsic constraints when applied to today's energy component profiles:

- Multiple part re-fixturing increases cumulative geometric error and handling time.

- Interpolated contours and undercuts are difficult or impossible without multi-axis continuous motion.

- Indexed approaches cannot optimally control tool engagement across complex surfaces, increasing tool wear and surface defects.

In practice, these limits translate to longer time-to-market and higher total cost of quality for new equipment families.

How five-axis gantry-moving-column centers restore process stability

Five-axis machines bring continuous multi-axis interpolation and greater spatial freedom. For large energy equipment, the core benefits are:

- Single-setup multi-face machining: reduces setup counts by 40–70% for typical large, asymmetric parts, dramatically lowering cumulative positioning errors.

- Optimized tool orientation: keeps optimal cutting geometry across complex surfaces, reducing chatter and improving surface integrity.

- Shortened process chain: eliminating intermediate fixtures and secondary operations shortens lead times and reduces handling-induced defects.

Setup reduction: 40–70%

Cycle time improvement: 20–45%

Scrap/rework reduction: 25–50%

Continuous 5-axis kinematics, rigid gantry structure, adaptive feed control and integrated thermal compensation.

Technical details that underpin machining stability

Five-axis platforms targeted at energy equipment often integrate several design elements to deliver consistent precision over long cycles:

1. Structural rigidity and thermal control

A gantry-moving-column layout provides high stiffness across large spans, lowering deflection under heavy cuts. Complementary thermal-management strategies — such as symmetrical guideway layouts, ball-screw cooling or thermal isolation of drive motors — reduce thermal drift. Typical thermal drift control targets are within 5–20 µm over an 8-hour production shift for premium systems.

2. Zero-backlash transmission and precision feedback

Zero-backlash reducers and high-resolution encoders deliver repeatability commonly in the 0.003–0.01 mm range depending on configuration, ensuring consistent tool-tip positioning during long contouring passes.

3. High-speed, high-torque spindle and tool management

A spindle that balances high speed with sufficient torque enables smoother cuts and faster material removal without inducing chatter. Integrated ATC (automatic tool changers) and predictive tool-life monitoring reduce unplanned stops that otherwise affect part-to-part consistency.

4. Intelligent control and adaptive cutting

Modern CNCs with adaptive feed and real-time monitoring adjust cutting parameters to compensate for tool wear and variable material conditions, typically improving achievable feedrates by 10–30% while maintaining surface quality.

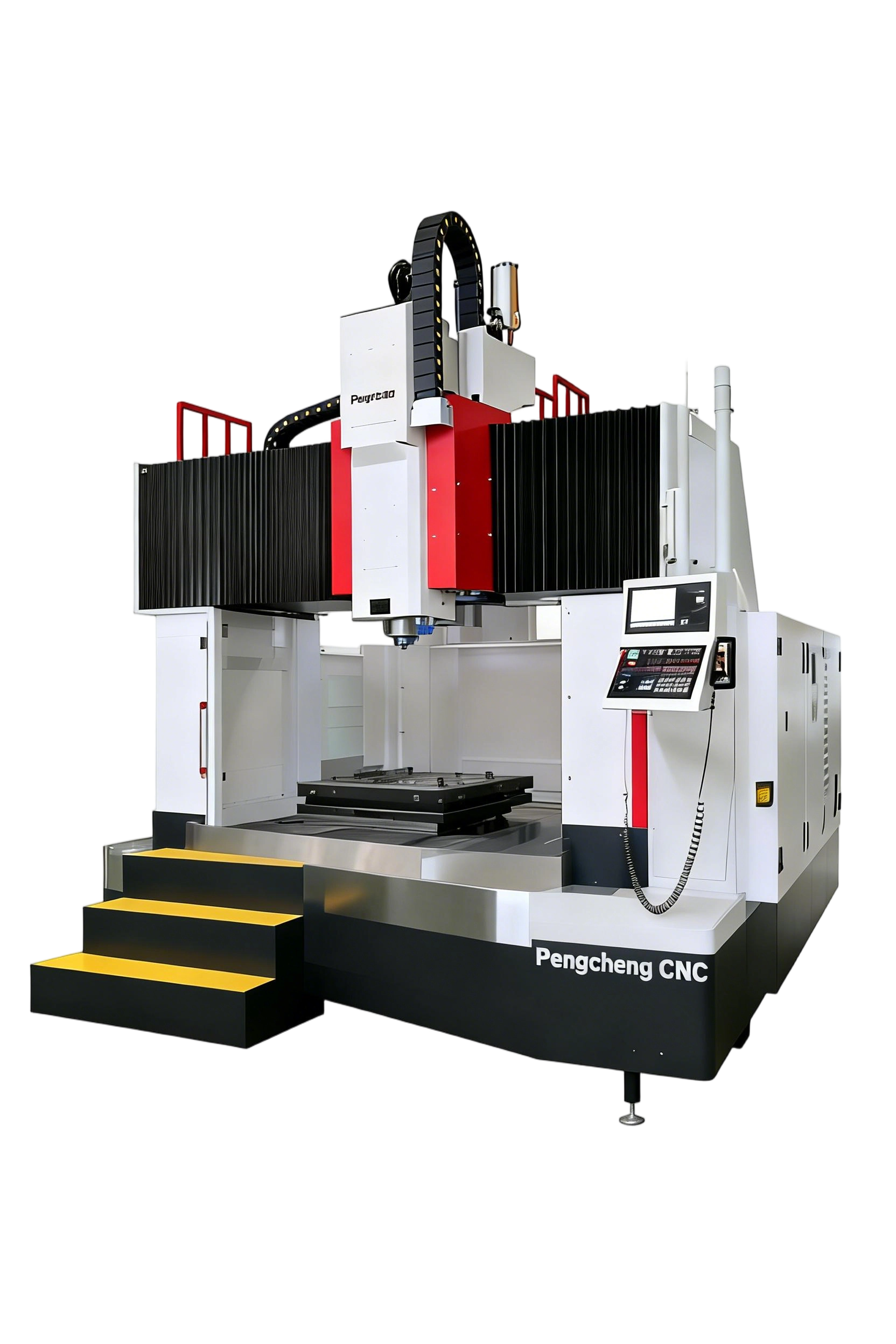

Application snapshot — Pengcheng CNC L30 in energy equipment production

The Pengcheng CNC L30 five-axis gantry-moving-column center is engineered for large-format energy components. Key attributes relevant to processing stability include rigid box-structure gantry, precision zero-backlash drives, a thermally balanced guideway layout and a control system optimized for long-cycle interpolation.

In production trials with large turbine housing prototypes, users reported:

- Reduction of total setups from 6 to 2 on average, cutting manual handling and index error sources.

- Cycle time reduction of approximately 30% on complex envelope machining through continuous 5-axis strategies and higher average feedrates.

- Yield improvement: first-pass acceptance rates increased by roughly 35%, lowering rework and machining scrap.

These figures are representative and depend on part geometry, material and shopfloor integration, but they illustrate how platform capability translates into measurable stability and quality gains.

Selection checklist for manufacturing decision-makers

When specifying a five-axis solution for energy equipment production, plant managers should evaluate:

- Work envelope matching: ensure the machine accommodates largest parts with maintenance access and fixturing strategy.

- Structural and thermal design: ask for finite-element and thermal compensation data; request reference drift figures over working shifts.

- Drive and feedback precision: review encoder resolution, backlash specifications and test reports demonstrating repeatability (aim for <0.01 mm where required).

- Control and software ecosystem: check CAM post-processor compatibility, collision-avoidance simulation and adaptive control functions.

- Service and spare support: evaluate regional service coverage, response SLAs and availability of trained commissioning personnel.

- Total cost of ownership: analyze expected throughput gains, quality improvements and projected payback horizon (many deployments see payback within 12–36 months depending on volume).

Trends shaping the next decade of five-axis in energy manufacturing

Several technological shifts will further embed five-axis machining into energy equipment production:

- Digital twins and predictive maintenance: real-time process models will anticipate tool wear and thermal effects before quality is affected.

- AI-driven process optimization: automated parameter tuning across batches to maximize material removal while preserving surface quality.

- Hybrid manufacturing: integration of additive and subtractive stages on a single platform to reduce material waste and part count.

Explore a five-axis solution tailored for energy equipment

Manufacturers seeking to reduce process variability and accelerate development cycles can evaluate the Pengcheng L30 as a production-proven option for large, complex components.

View Pengcheng L30 Specifications and Technical ServicesManufacturers evaluating pathway improvements should request on-site demonstrations and measured part reports that reflect their most demanding geometries. Real-world validation under production loads remains the most reliable way to quantify stability improvements and secure management buy-in.